One Block at a Time

Segmental paving systems have a long, proven history of performance. The Romans used cobbles to pave roads as early as 500 B.C. Some of those same ancient roads are still in use today. Pavers are built to stand the test of time and many advancements in the production and installation of the units have allowed them to become more economical in everyday applications. Not only do pavers look better than concrete or asphalt, they will outperform them too. A properly installed paver system will outlive concrete, asphalt, and even quite possibly the owners and the installers.

Our installers work with block every day and are equipped with the latest and greatest tools and equipment to get the job done. Many of our team possess industry-specific education and certifications and are keeping up to date with new products and installation methods. We will provide you with a quality finished product within a very fast timeline.

We Install:

- Driveways

- Traditional Sand-Set Pavers

- Permeable Pavers

- Clay Pavers

- Heated Paver Systems

- Commercial Pavements

- Patios & Pool Decks

- Inlays & Custom-Cut Designs

- Walkways

The Process

On the right projects, pavers can go in FAST. Many small driveways can go from demo to full completion in 2-3 days.

- Layout and Planning

- Once you have chosen a paver, accepted a bid from Konstanty, and we have a signed contract, we will meet with you at the site to mark out the layout and discuss any details that have not been previously addressed. This allows the layout to be confirmed so that excavation can occur quickly and without too many changes. On most driveway projects, this happens the morning we begin.

- Demo and Excavation

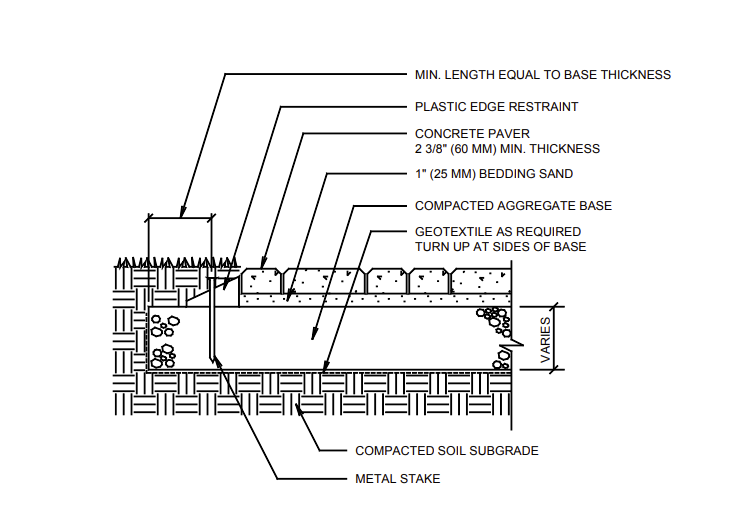

- Any existing concrete or asphalt is torn up and hauled off the site as well as any fill soil. This process is the noisiest part of the project as there are usually multiple machines running and dump trucks coming in and out. Once the full depth of excavation is reached, fabric is laid and base rock is spread.

- Compaction and Fine-Tuning

- All of the aggregate for the base is brought to the proper heights and compacted. Proper compaction is one of the most important steps to ensure you are left with a long-term product.

- Screeding, Laying, and Cutting

- A 1″ layer of sand is spread for bedding material and pavers will begin to be laid. The edge pavers will also be cut at this point and the border pavers will be installed.

- Final Compaction & Joint Sand

- Once all the pavers have been laid and cut, the surface is compacted with a small plate compactor. This levels any uneven pavers, and pushes some of the sand from underneath into the joints creating an interlock between the pavers. Polymeric joint sand is then applied. Once wet down, the joint sand hardens to fully interlock the surface and prevent any weeds from growing in the joins.

- Cleanup and Completion

- Once all the work has been completed, the project is cleaned up and any extra materials are hauled away. Once we have done a final walkthrough, we are ready to de-mobilize and get to the next one.

Product Links

We install pavers from a number of different manufacturers, but there are a few of the more common brands we work with. Holland pavers in a herringbone pattern are by far the most popular selection and have some price advantages, but there are many more options available. We have listed some of the more popular options below.